COVID-19 is an infectious disease that infects people of all ages with underlying medical problems. If infected, you may experience little to no symptoms. For those who do experience severe symptoms, the disease will move down your respiratory tract making it extremely hard to breath.

As the COVID-19 outbreak started spreading across the nation in February, one terrifying reality became apparent: the United States only has the capacity to ventilate about 170,000 patients, while 960,000 patients were projected to require mechanical ventilators.

That’s when a team of Mass General Hospital anesthesiology residents -- led by Dr. Richard Boyer -- decided to do something about it. Dr. Boyer founded and launched the CoVent-19 Challenge, an eight-week hackathon hosted on the GrabCAD Community to design a rapidly deployable, minimum viable mechanical ventilator for patients with COVID-19-related ventilator-dependent lung injury.

The Most Important GrabCAD Challenge

The CoVent-19 Challenge (also sponsored by Ximedica, Valispace, HackFund and Yelling Mule) is most likely the most important challenge the GrabCAD Community has ever been invited to host. This challenge invited designers and engineers from around the world to design a piece of equipment that could save thousands.

And GrabCAD Community, you did not disappoint.

Two-hundred-and-thirteen entries were submitted to the GrabCAD Community. Our team of judges, including Scott Crump, the inventor of FDM and co-founder of Stratasys, had the task of selecting seven of the designs to move on into the next stage.

The Finalists

The following finalists were selected based on the viable ventilator designs, which needed to demonstrate safety, reliability, and manufacturability -- while minimizing cost and complex software and electronics.

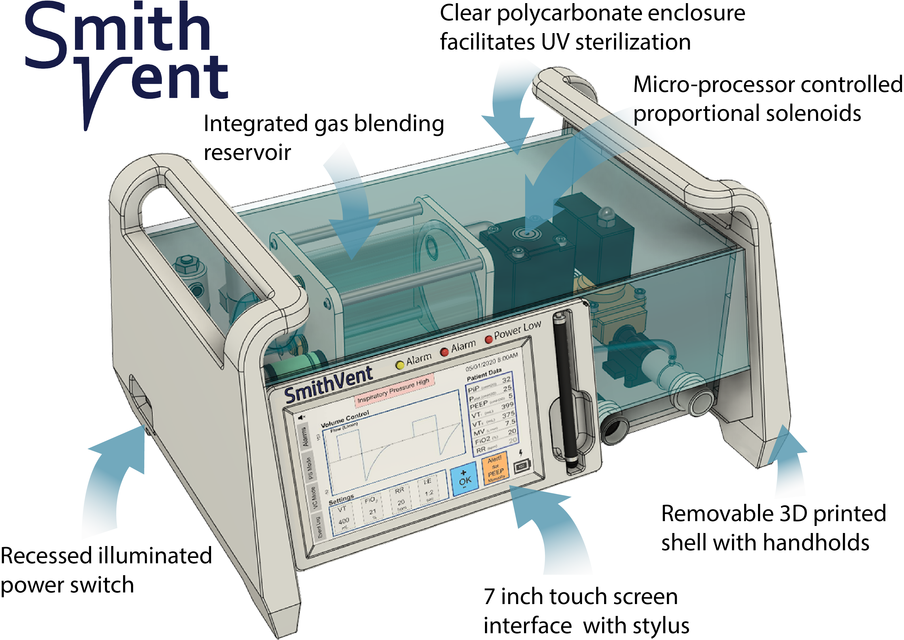

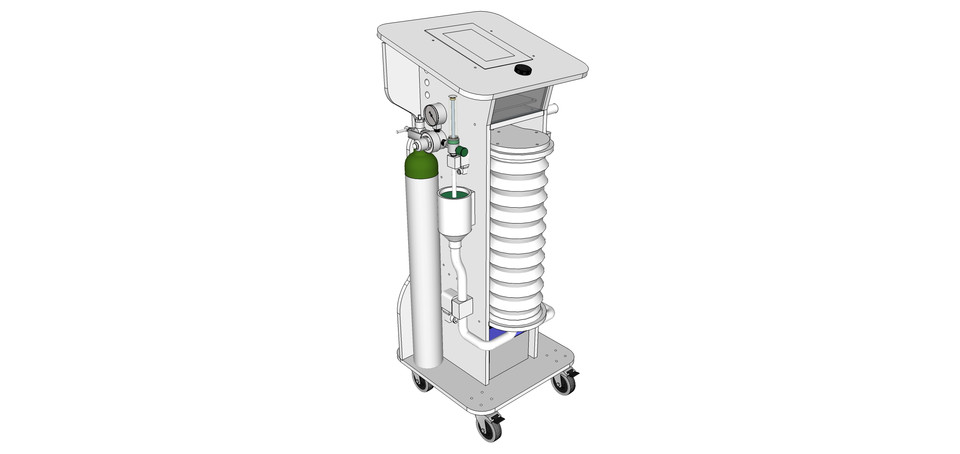

This team is made up of Smith College (Northampton, Mass.) engineering alumni and friends. Their design focuses on a simplified, cost-effective, rapidly-manufacturable pneumatic ventilator tailored to COVID-19 patient needs and designed for ease of use by healthcare workers.

“The SmithVent design will allow gentle air delivery to the patient, proning if necessary, and liberation from mechanical ventilation with its pressure support mode," explains the team. "Our manufacturing strategy utilizes mainly readily-available off-the-shelf components, thereby reducing complex machining and supporting compatibility with current medical equipment.”

Team InVent Pneumatic Ventilator

This design was submitted by three firms, Fuseproject, Cionic and Accenture. Together, the team worked to create a pneumatic valve ventilation system.

“Our design maximizes use of Stratasys’ Advanced PolyJet printing technologies and library of materials for optimized assembly," explains the team. "Combining outer shell and housing, the unit leverages multi-material and multi-color printing functionality to include a built-in gasket, built-in mixing tank for air, venting, fasteners for assembly, and even exterior UI details like buttons and icons.”

This global team is made up of engineers and healthcare workers. The design aims to help developing countries who can build the affordable ventilators themselves, with parts available from local supply chains.

Our design is unique from others in that it utilizes a sophisticated ventilation system (involving a high-performance fan, pressure sensors, and a microcontroller), simplifies assembly and manufacturing, and relies on high quality software that will also be open source. -- Alex Plazas, Team RespiraWorks.

Baxter Academy alumni, educators and students designed a ventilator specifically for a pandemic, with a focus on easy assembly.

“The Baxter Ventilator was designed to be built by individuals with limited skills in distributed locations, as well as at scale," explains the team. "A single person can assemble a ventilator a day with an only an Allen set and crescent wrench following Ikea type assembly instructions and videos."

This design was submitted by Ross Hunter of Armadilla (Edinburgh, Scotland). It was designed to help combat COVID-19 for developing countries, as you can use off-the-shelf components.

The OP Vent team submitted an open source ventilator design that uses a proportional solenoid valve.

This Colombia-based engineering team submitted a low cost mechanical ventilator.

What’s Next

The seven finalists have already started working with medical and technical experts to build and test functional prototypes. Stratasys application engineers will also provide 3D printing consulting to the finalists.

By May 27th, the functional prototypes should be finalized and a winner announced in June. Stratasys is giving the top three winners a total of $10,000 in credits they can use for 3D-printed parts from Stratasys Direct Manufacturing.

The ultimate reward for the Community’s contribution will be when the top ventilator design is brought to market and approved by the FDA. If you have the capacity to 3D print face shields or nasal test swabs, visit the Stratasys COVID-19 response page!

And the Final Winner Is

On July 1, 2020, Team SmithVent was announced as the winner of the entire challenge! Congratulations Team SmithVent.

Updated July 2020